When a company considers producing a component using Metal Injection Molding (MIM), one of the first questions is: what will it cost? The answer depends on three key elements: the material, the design, and the configuration of the part.

In this article, we’ll not only break down the factors that impact the cost of a MIM part, but also compare it to investment casting, helping you decide which technology better suits your production needs.

1. Material matters

The choice of material has a direct impact on cost.

- First, the raw material price. Stainless steels like 316L and 17-4PH are around 30% more expensive than carbon steels such as FN08 or 42CrMo4. On top of that, metal powders used in MIM are typically 10 to 15 times more costly than raw materials like bar or ingot used in traditional manufacturing.

- Second, the sintering process. Stainless steels require slower sintering speeds and must be processed in a hydrogen atmosphere, which increases production time and cost. In contrast, carbon steels can be sintered faster—up to 30–40% quicker—in a nitrogen atmosphere, making them more cost-effective in high-volume runs.

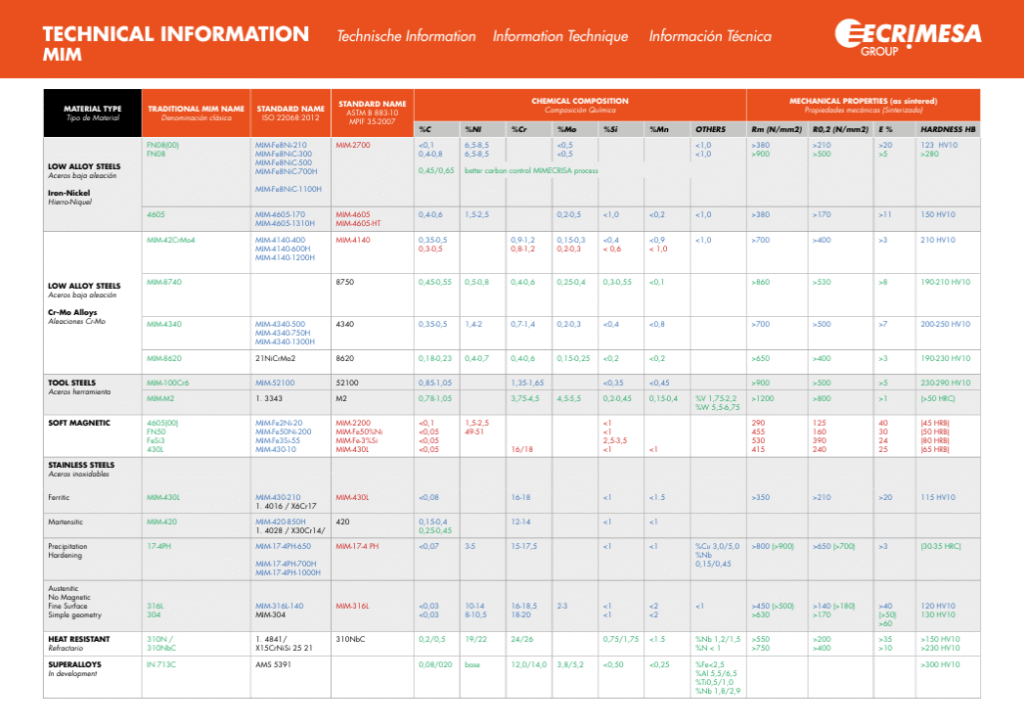

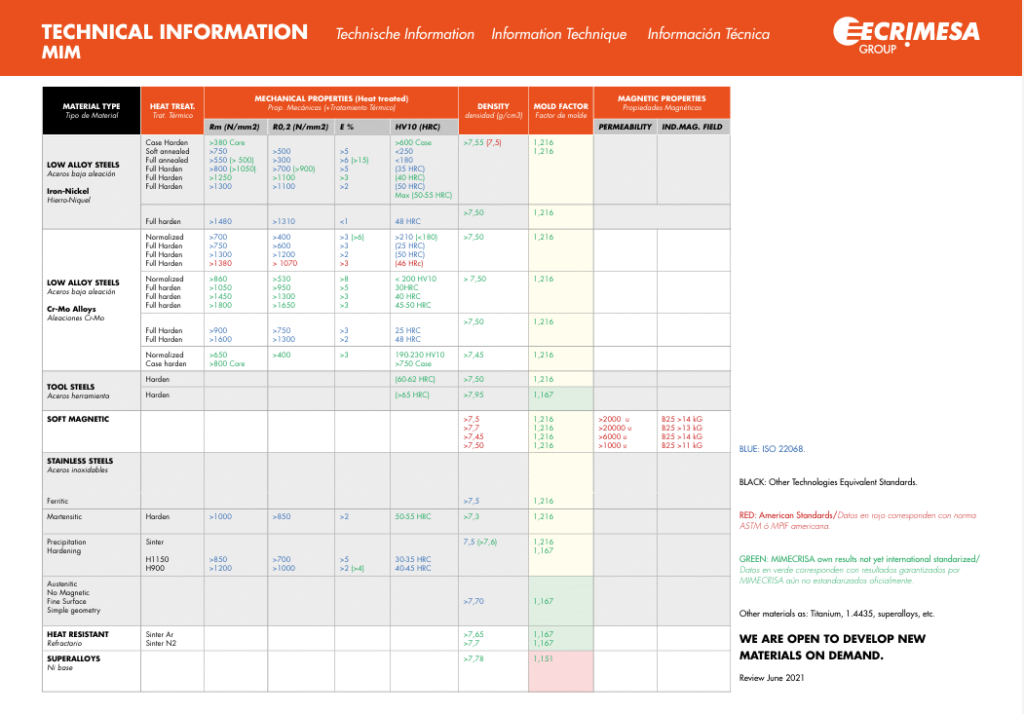

Our MIM portfolio includes the following material options:

2. Size and geometry

The size and shape of a MIM part directly affect both manufacturing efficiency and total cost. One key factor is sintering capacity. At MimecriUSA, parts are processed in 200 x 200 mm molybdenum trays. The more parts that fit in each tray, the lower the cost per unit. This applies to both continuous and batch furnace setups.

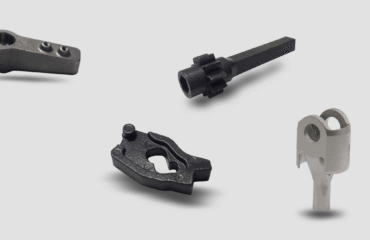

Based on our experience, the most efficient weight range for MIM parts is between 0.5 grams and 40 grams. However, we also produce parts that exceed 150 grams when their geometry allows for reduced machining and other secondary operations, which makes them more competitive compared to alternative technologies.

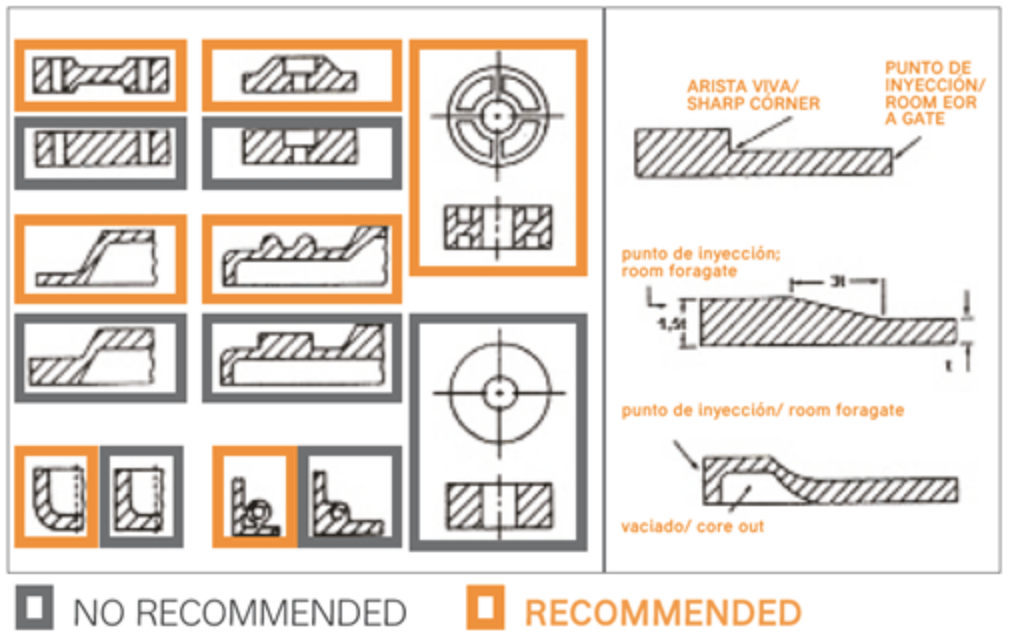

Design is just as important as size. To optimize the process, parts should avoid sharp edges, include smooth transitions, and provide flat support surfaces. These features help stabilize the piece during sintering, prevent defects, and reduce the need for extra handling or post-processing. A well-designed part is easier to manufacture, more consistent in quality, and more cost-effective overall.

3. Smart design reduces cost

Designing for MIM is more than aesthetics. Rounded edges, flat support areas, and homogeneous wall thicknesses are critical for material flow during injection and stability during sintering. Good design minimizes deformation risks and reduces the need for extra fixtures or post-processing, which translates directly into lower costs.

Parts should avoid sharp edges and include generous radii to ensure smooth material flow during injection. This helps prevent segregation and reduces the risk of cracks after sintering.

It is also important to provide clear space for the injection point and maintain uniform wall thickness. Since MIM uses steel powder, proper flow is more difficult than with plastics, so geometry must support a clean, even fill.

Flat support areas are another key factor. Without them, parts require custom sintering fixtures, which limit furnace capacity and increase costs. Designing parts that rest securely during processing improves both efficiency and quality.

Finally, for low-alloy or carbon steel parts that need heat treatment, the design should help avoid distortion. Correct placement and support features make it easier to maintain dimensional accuracy throughout the process.

MIM vs investment casting: which is more cost-effective?

For high-volume projects, MIM often offers better cost performance than investment casting. In a case study of 45,000 parts per year, the total cost per part was over 20% lower with MIM — thanks to the elimination of machining steps and tool amortization.

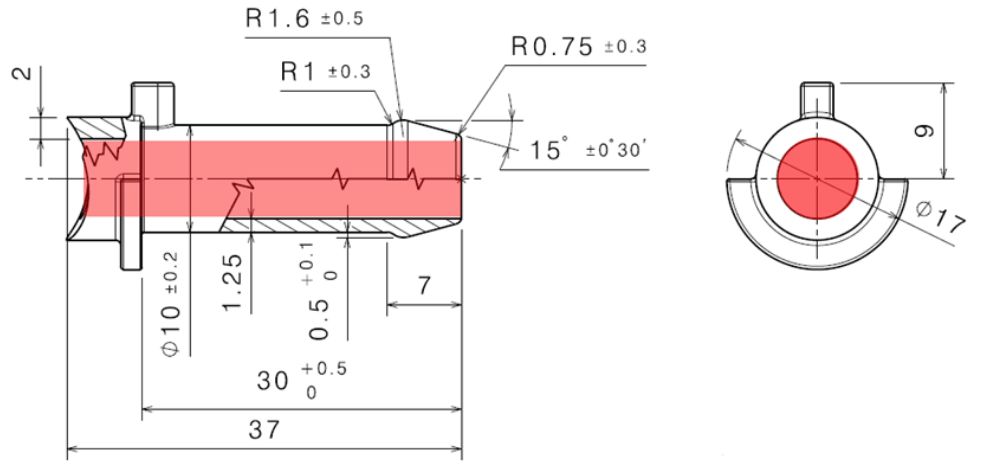

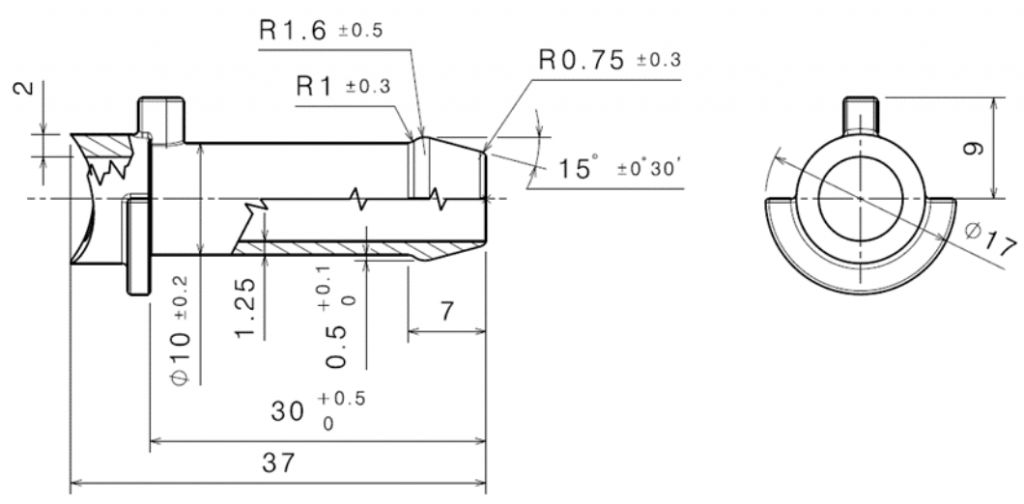

Making a comparison between MIM and Microfusion of a potential part:

For an annual consumption of 45,000 pieces/year the cost study would be:

| MICROFUSION | MIM | |

|---|---|---|

| PIECE | 1 € | 0,94 € |

| MACHINING | 0,54 € | NO |

| MACHINING TOOL | 1.800 € | NO |

| MOLD | 6.500 € | 16.000 € |

Microfusion design measures

Estimating the amortization of the tooling on the first 45,000 pieces, the result would be:

| MICROFUSION | MIM |

|---|---|

| 1,72 € | 1,29 € |

Cost comparison: Microfusion and MIM

High-precision MIM manufacturing in the USA

At MimecriUSA, our MIM facility in Thomasville, GA, is optimized for efficiency and high-volume production. With automated injection lines, catalytic debinding, and continuous sintering furnaces, we produce millions of parts annually with consistent quality.

For complex, high-precision components, MIM can significantly reduce unit costs compared to investment casting, especially when machining is no longer needed.

Looking for a cost-effective, scalable solution for your metal parts?

by

by