At Mimecriusa, our comprehensive catalog of MIM (Metal Injection Molding) materials is designed to meet the diverse needs of industries such as automotive, industrial machinery, defense, medicine, and even sports equipment. Thanks to the wide range of available compositions and heat treatments, we are able to serve an extensive variety of applications with precision and performance.

Over the years, our expertise in manufacturing metal parts using MIM technology has earned recognition at an institutional level. Our active involvement in the development of the international ISO standard ISO 22068 – “Sintered Metal Injection Moulded Materials – Specifications” demonstrates our commitment to innovation and quality in this field.

While we work with several materials, steel remains our primary focus. In this article, we’ll explore the types of steels we manufacture using MIM, their applications, and their key mechanical and chemical properties.

Overview of MIM steels

Our MIM materials are categorized by type and presented with detailed technical data. The following tables provide insights into:

- Nomenclature and chemical composition according to ISO and ASTM standards.

- Mechanical properties based on heat treatment processes.

- Special alloys like soft magnetic steels, stainless steels, and high-performance materials for extreme conditions.

Table summary

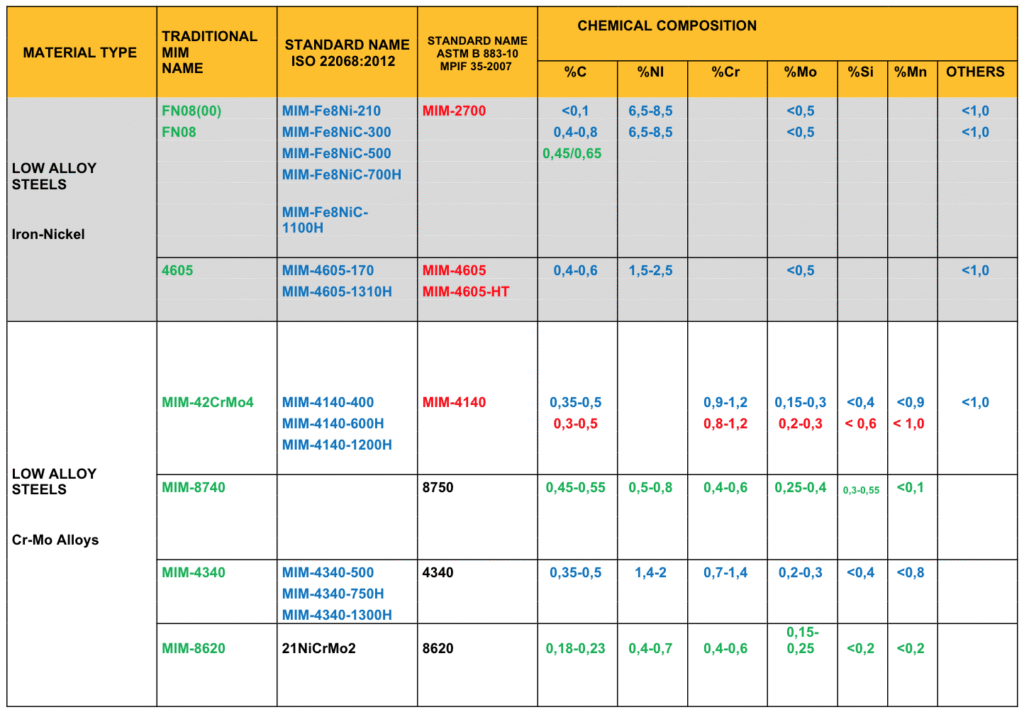

- Table 1 – Nomenclature and chemical composition of low alloy steels

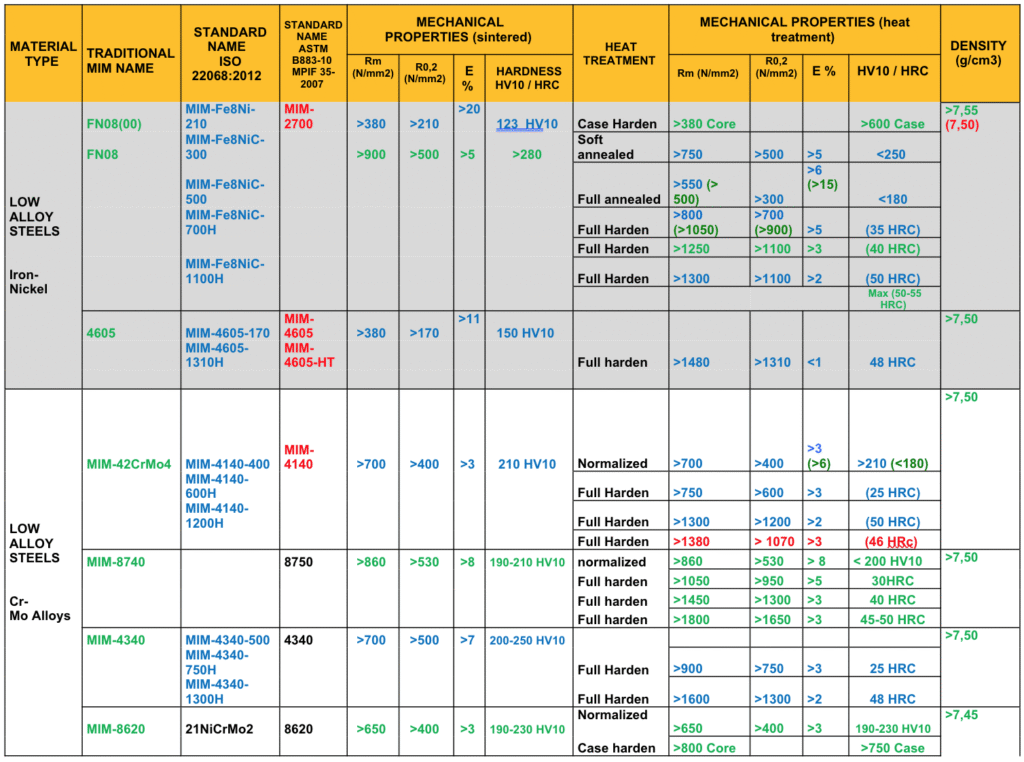

- Table 2 – Mechanical properties of low alloy steels (by heat treatment)

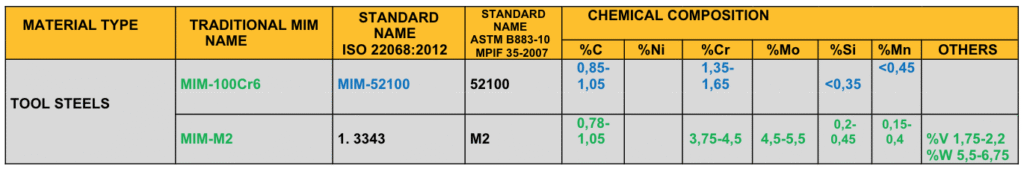

- Table 3 – Chemical composition of tool steels

- Table 4 – Mechanical properties of tool steels

- Table 5 – Soft magnetic steels available

- Table 6 – Mechanical and magnetic properties of soft magnetic steels

- Table 7 – Classification and chemical composition of stainless steels

- Table 8 – Mechanical properties of stainless steels (by heat treatment)

Low alloy steels

Low alloy steels are carbon steels enhanced with 1%–4% of alloying elements to improve mechanical performance. These materials are widely used in automotive, industrial machinery, defense, and tooling applications.

After sintering, these steels often undergo heat treatments such as quenching, tempering, or carburizing to reach their final properties. Surface treatments, including bluing, nickel plating, zinc plating, or QPQ, may also be applied for enhanced corrosion resistance.

Table 1: Nomenclature and chemical composition

This table outlines the classification of low alloy steels based on ISO and ASTM standards, along with their corresponding chemical composition. It also includes steels adapted from DIN/EN and SAE specifications, even if not yet standardized under ISO 22068 for MIM.

Of note are high-nickel steels derived from traditional powder metallurgy, which benefit from significantly improved mechanical properties thanks to the high densities achievable through MIM.

Table 2: Mechanical properties by heat treatment

This table presents the mechanical properties of each low alloy steel, as influenced by various heat treatments. It includes:

- Blue values: Minimum properties defined by ISO 22068

- Green values: Typical results obtained in our laboratory, based on our in-house processing

One of our most frequently used materials is FN08, a low alloy steel with excellent behavior under MIM conditions. Our extensive experience with this steel has allowed us to optimize performance and production efficiency.

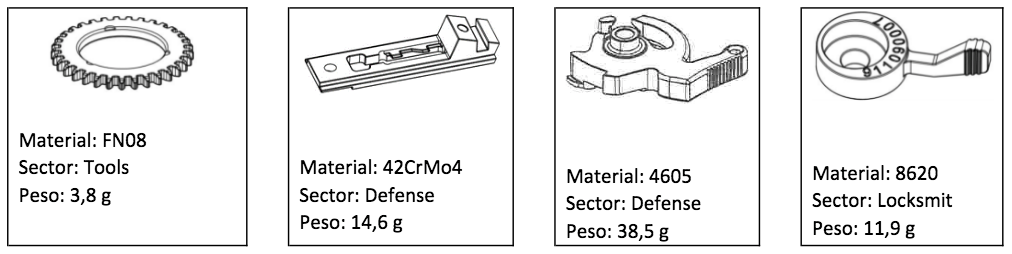

Application examples

Low alloy steels manufactured by Mimecriusa are used in:

- Automotive components

- Defense systems

- Locks and security products

- Machine tools

- General industrial parts

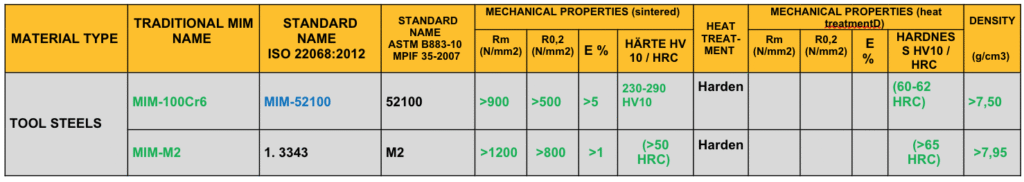

Tool steels

Tool steels are formulated for applications requiring high wear resistance and hardness. With heat treatment, these steels can reach hardness levels of over 65 HRC. They contain elements like chromium, molybdenum, and vanadium, which form hard carbides in the microstructure.

Table 3: Chemical composition of tool steels

This table details the chemical makeup of the tool steels used, based on relevant ISO and ASTM classifications. These compositions are optimized to deliver outstanding performance after heat treatment, particularly in applications where dimensional precision and resistance to abrasion are critical.

Table 4: Mechanical properties according to heat treatment

Here, we present the mechanical properties of tool steels as a function of the heat treatment applied. With proper processing, hardness values can exceed 65 HRC, making these steels ideal for tooling, cutting, and high-stress environments.

Values in the table reflect:

- Minimum standardized requirements

- In-house test results from our own laboratory processes

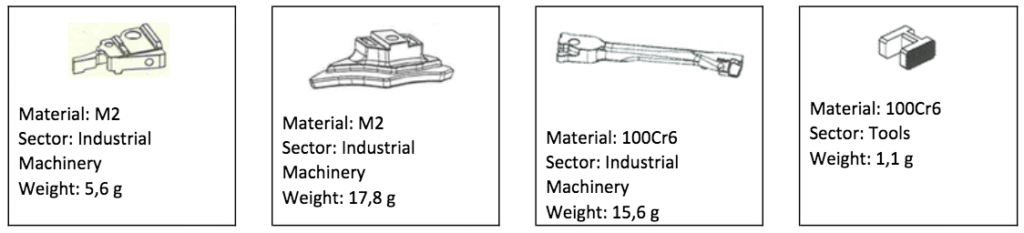

Application examples

Our tool steels are used in sectors such as:

- Industrial machinery: components requiring high surface hardness and durability

- Cutting tools and dies

- Defense applications with high mechanical stress

- Precision engineering and mechanical assemblies subject to wear and impact

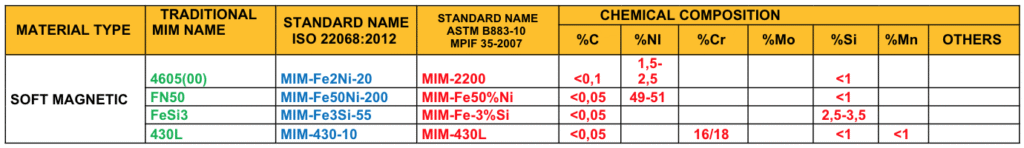

Soft Magnetic Steels

Soft magnetic steels are engineered to magnetize and demagnetize quickly under an electromagnetic field, making them ideal for applications like sensors, actuators, transformers, and electric motors.

These materials are crucial in industries that rely on electromagnetic performance, such as automotive electronics, industrial automation, and medical devices.

Table 5: Soft magnetic steels available

This table outlines the types of soft magnetic steels used in our MIM process, including their chemical composition, material codes, and basic magnetic attributes.

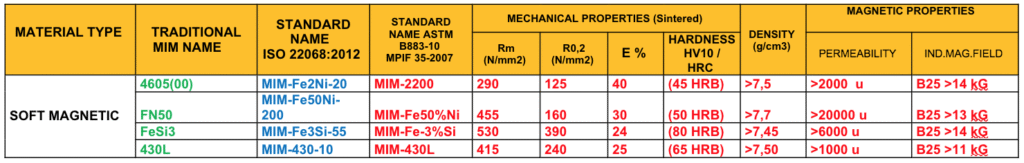

Table 6: Mechanical and magnetic properties

Here we present both mechanical (tensile strength, elongation, hardness) and magnetic properties (permeability, magnetic induction, density), offering a full profile of each alloy’s capabilities.

Application examples

Soft magnetic steels are used in:

- Magnetic sensors

- Electromechanical actuators

- Rotating machinery components

- Miniaturized medical devices

- Any design requiring magnetic responsiveness with structural strength

Stainless steels

Stainless steels are known for their exceptional corrosion resistance, especially in aggressive environments. They are highly alloyed steels, with chromium content above 12%, and low carbon levels to maintain resistance.

Thanks to the MIM process, we achieve excellent surface finishes, making stainless steels ideal for both functional and aesthetic components.

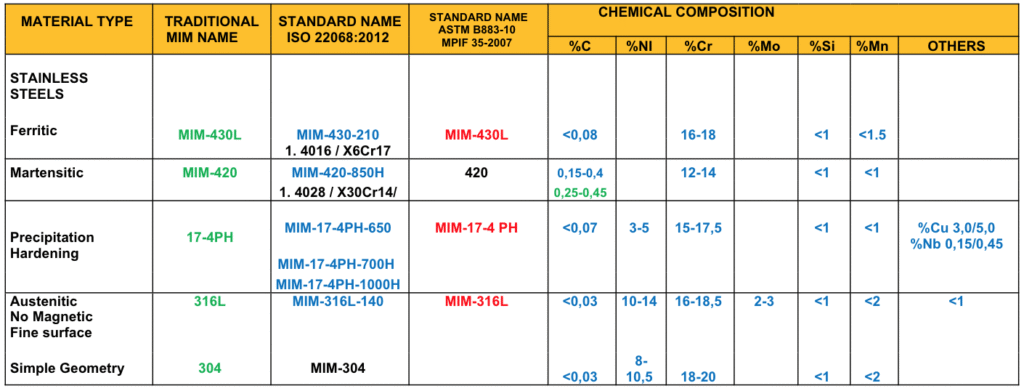

Table 7: Classification and chemical composition

This table outlines the four main categories of stainless steels (ferritic, martensitic, precipitation hardening, and austenitic), with corresponding chemical compositions and standard names (ISO/ASTM).

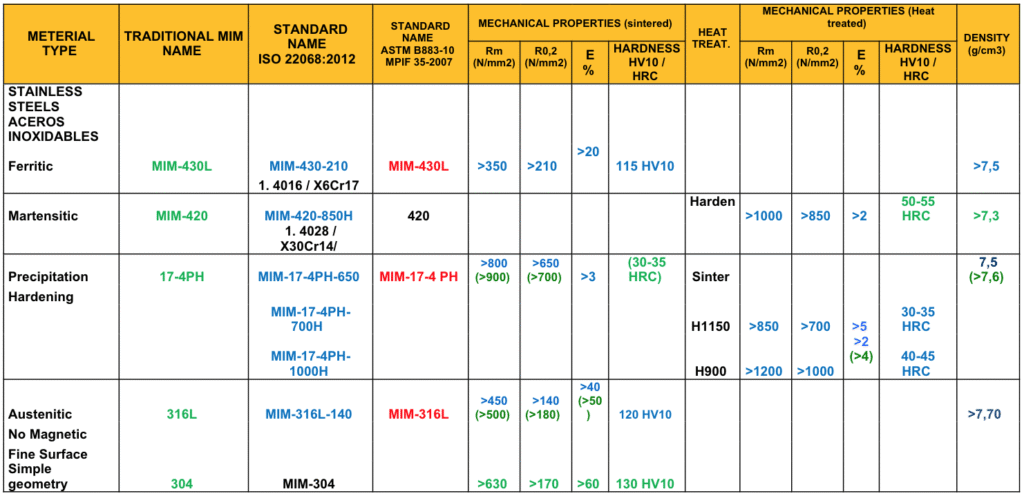

Table 8: Mechanical properties by heat treatment

Mechanical characteristics are detailed according to applied heat treatments, including:

- Tensile/yield strength

- Elongation

- Hardness This is especially relevant for alloys like 17-4PH, which offers an excellent balance of mechanical strength and corrosion resistance.

Application examples

Stainless steels we produce, are used in:

- Medical equipment and surgical tools

- High-end jewelry and consumer products

- Automotive and aerospace components

- Defense and sporting equipment

We’ve conducted in-depth studies on 17-4PH corrosion behavior, including testing in salt spray chambers. Our findings were shared at the EUROPM 2018 Congress, underlining the importance of heat treatment and binder phase segregation in corrosion performance.

Other materials: superalloys & refractories

Beyond steels, we also offer nickel-based superalloys and refractory materials for parts that must withstand extreme heat and demanding environments. These are often used in aerospace, defense, and energy sectors.

To learn more about the MIM materials we use:

Download our materials guide (MIM Material Information Sheet).

MIM today and tomorrow

Metal Injection Molding has become one of the most competitive and precise technologies for producing complex metal parts. It enables the production of parts that would otherwise be costly or impossible using traditional techniques.

With over three decades of experience, we have positioned ourselvesas a global leader in MIM. Our extensive portfolio, backed by strong R&D, allows us to offer engineers and manufacturers the flexibility to design and deliver innovative, high-quality solutions.

From automotive components to surgical tools, the future of MIM, and of precision metal part manufacturing, looks promising, and we are proud to be leading the way.

Contact our team for technical advice on choosing the right material or to request a quote for your next project.

by

by