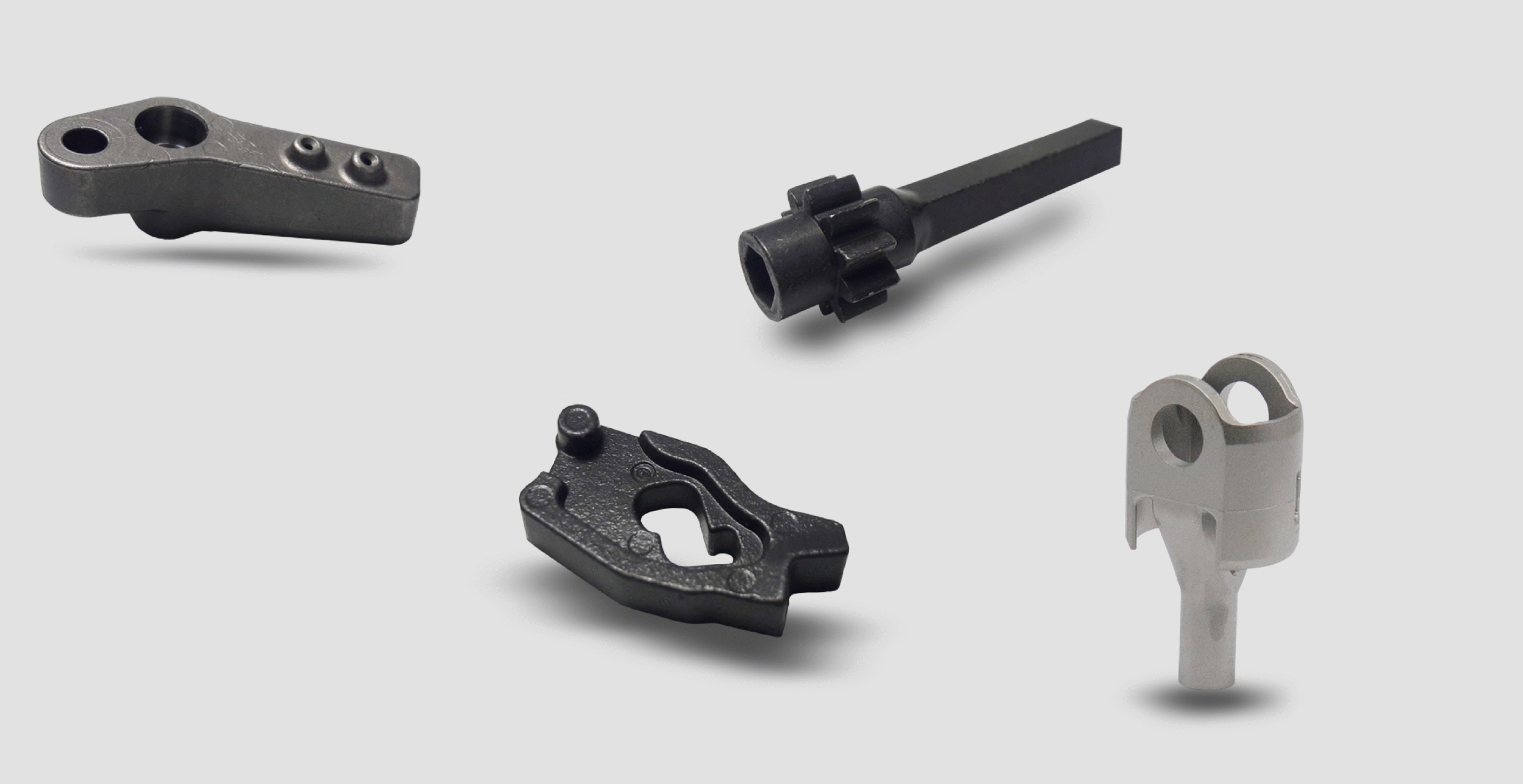

Metal injection molding (MIM) is an advanced manufacturing process that merges the design flexibility of plastic injection molding with the strength and durability of metal. It’s ideal for producing small, intricate, and high-performance components in large volumes.

In this article, we’ll walk through the key advantages and disadvantages of MIM to help you determine whether it’s the right solution for your product, and how mimecriUSA can support you in making that decision with confidence.

What is metal injection molding?

MIM begins with blending ultra-fine metal powders with a thermoplastic binder to form a moldable feedstock. This feedstock is injected into a mold to create a “green part.” After molding, the binder is removed in a debinding process, and the part is sintered at high temperatures. The final result is a fully dense, net-shape metal component with precise tolerances and excellent mechanical properties.

Advantages of Metal Injection Molding

- Complex geometries and tight tolerances

MIM is ideal for producing parts with intricate shapes, undercuts, internal threads, and thin walls that are difficult or cost-prohibitive to achieve through conventional machining or casting. - Minimal material waste

Unlike subtractive methods that generate scrap, MIM uses nearly all of the input feedstock, resulting in significantly lower material waste and better material cost-efficiency. - Cost efficiency at scale

Though tooling represents an upfront investment, MIM becomes highly cost-effective for high-volume production. Once the tooling is in place, each part can be manufactured consistently and affordably. - Excellent mechanical performance

MIM components are typically 95–99% dense, providing strength, durability, and performance characteristics comparable to wrought metals. This makes them suitable for demanding applications in aerospace, medical devices, and automotive systems. - Smooth surface finishes

MIM parts have fine surface finishes straight out of the mold, often eliminating the need for secondary finishing processes. - Wide material options

MIM supports a broad range of metals and alloys, including stainless steel, low alloy steel, tool steel, titanium, and even magnetic or corrosion-resistant materials.

Disadvantages of Metal Injection Molding

- High tooling costs

MIM requires custom-designed molds, which can represent a significant upfront cost. This makes the process less economical for prototyping or small production runs. - Size limitations

The process is best suited for small to medium-sized parts—typically under 100 grams. Larger components are more challenging to sinter uniformly and may experience warping or density issues. - Longer production timelines

The MIM process includes several stages—molding, debinding, sintering—which can extend lead times compared to simpler manufacturing techniques. - Limited post-processing flexibility

Once sintered, MIM parts are extremely hard and dense, which can make machining or post-production modifications difficult and expensive.

Is MIM the right fit for your next project?

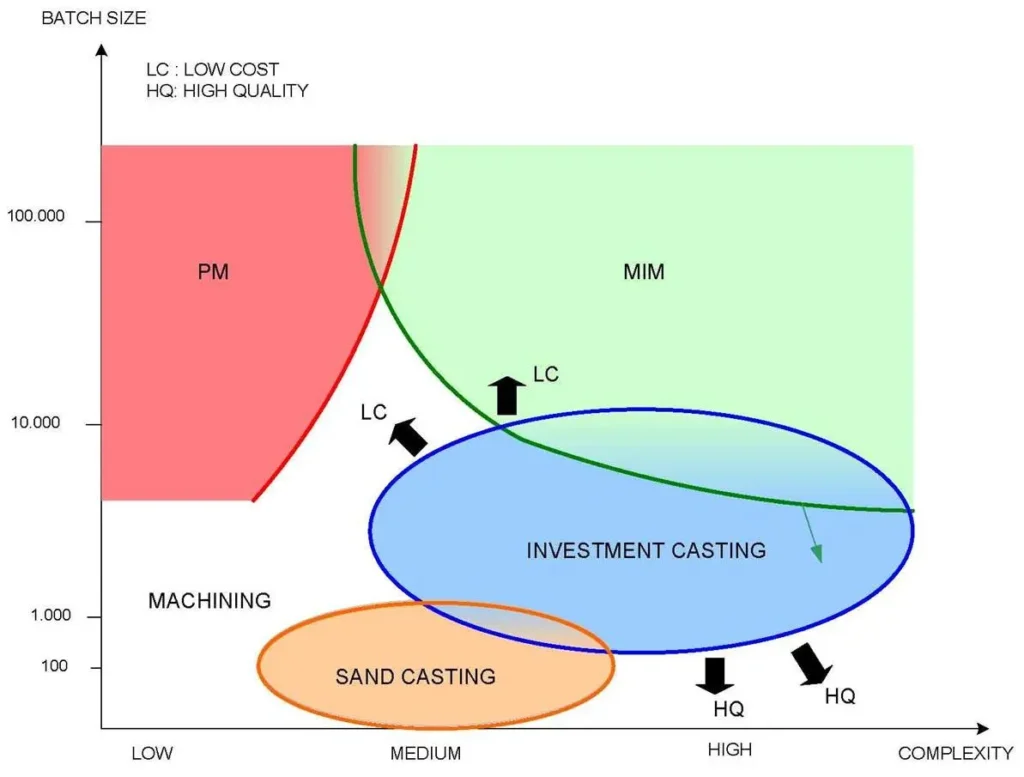

Metal injection molding offers unique advantages in precision, complexity, and scalability. However, it may not be the best option for every application. Projects that require small, high-volume, high-performance parts with tight tolerances are strong candidates. For larger parts or lower production volumes, other methods might be more appropriate.

At mimecriUSA, we work closely with engineers and sourcing teams to assess whether MIM aligns with their design, performance, and cost goals. If it’s a good fit, we guide your team from prototyping through full-scale production.

Why partner with mimecriUSA?

As a trusted leader in metal injection molding, mimecriUSA combines deep technical knowledge with manufacturing agility. We offer:

- Full-service MIM capabilities

- Material and process optimization

- Scalable production

- Dedicated engineering support

- Consistent quality control

Get in touch today to find out if MIM is the right path for your next innovation.

by

by