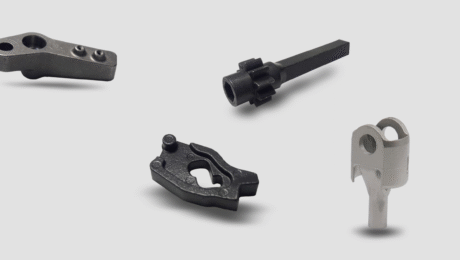

Metal Injection Molding: materials and applications

At Mimecriusa, our comprehensive catalog of MIM (Metal Injection Molding) materials is designed to meet the diverse needs of industries such as automotive, industrial machinery, defense, medicine, and even sports equipment. Thanks to the wide range of available compositions and heat treatments, we are able to serve an extensive variety of applications with precision and

- Published in MIM

Design rules for MIM parts

Metal Injection Molding (MIM) is one of the most efficient technologies for producing small and complex metal components with high precision. At MimecriUSA, we specialize in custom MIM parts manufactured in the USA, supporting sectors like automotive, defense, aerospace, and medical. Our experience shows that good design is critical to ensure functional performance, dimensional reliability,

- Published in MIM

Understanding the MIM process step by step

Metal Injection Molding (MIM) is a powerful technology for producing small and medium-sized metal parts with complex geometries and tight tolerances. It combines the design freedom with the strength of sintered metal, making it ideal for high-precision components in industries like automotive, aerospace, and medical devices. In this article, we break down each stage of

- Published in MIM

What determines the cost of a MIM part?

When a company considers producing a component using Metal Injection Molding (MIM), one of the first questions is: what will it cost? The answer depends on three key elements: the material, the design, and the configuration of the part. In this article, we’ll not only break down the factors that impact the cost of a

- Published in Industry 4.0, MIM

Is metal injection molding right for your product?

Metal injection molding (MIM) is an advanced manufacturing process that merges the design flexibility of plastic injection molding with the strength and durability of metal. It’s ideal for producing small, intricate, and high-performance components in large volumes. In this article, we’ll walk through the key advantages and disadvantages of MIM to help you determine whether

- Published in MIM

Metal injection Molding for the U.S. defense industry

Metal injection molding (MIM) delivers the precision, strength, and efficiency required by modern defense applications. Whether used in weapon systems, optical devices, or mechanical subassemblies, these components must meet demanding performance standards under extreme conditions. At MimecriUSA, we manufacture small, complex metal parts using MIM—ensuring consistent quality and high structural integrity. Samples of metal parts

- Published in MIM

Connect with our MIM Manufacturing Facility in Thomasville, GA

With a tradition spanning over six decades in the metal parts manufacturing industry, we are just a few months away from the imminent opening of our new MIM (Metal Injection Molding) manufacturing plant in Thomasville, GA, USA. Our group has firmly established itself as a leader in the production of high-quality metal components over the

- Published in Industry 4.0, MIM

by

by