Metal injection molding (MIM) delivers the precision, strength, and efficiency required by modern defense applications. Whether used in weapon systems, optical devices, or mechanical subassemblies, these components must meet demanding performance standards under extreme conditions. At MimecriUSA, we manufacture small, complex metal parts using MIM—ensuring consistent quality and high structural integrity.

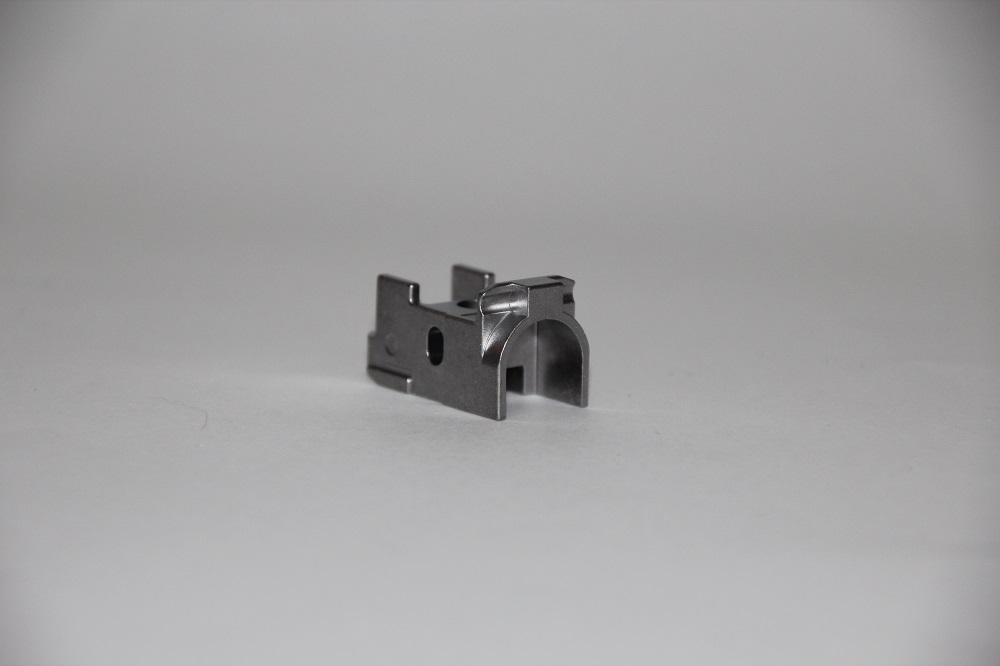

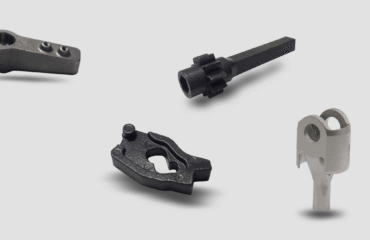

Samples of metal parts for the defense sector

Key applications of MIM in defense

MimecriUSA supports a broad range of defense programs with MIM parts engineered for durability and precision. These components are found in applications where strength-to-weight ratio, complexity, and performance are critical—such as firearm internals, locking mechanisms, guidance systems, and enclosures for sensitive electronics or optics.

By collaborating closely with contractors, we optimize part geometry for manufacturability, reducing secondary operations, minimizing weight, and ensuring compliance with strict technical requirements. From material selection to final inspection, we ensure every part is mission-ready.

Why MIM is the right technology for defense

MIM combines the design flexibility of plastic injection molding with the mechanical strength of sintered metal. It’s ideal for producing intricate, high-density parts with tight tolerances and minimal post-processing.

Key advantages of MIM for defense components:

- Dimensional tolerances up to ±0.5%

- High material density (up to 98%)

- Excellent surface finish (Ra 0.8 – 1.6)

- Ability to produce complex geometries without machining

- Consistent quality in high-volume production

This makes MIM particularly cost-effective for components under 100 grams—such as pins, locking systems, housings, optical parts, and micro-mechanical elements.

Samples of metal parts for the defense sector

Certified local manufacturing in the U.S.

MimecriUSA operates from Thomasville, Georgia, offering MIM production aligned with CQI-9 and AS9100 standards. The facility is equipped with automated injection systems, catalytic debinding units, and both continuous and batch sintering furnaces, allowing for process control across varying production volumes.

Material selection includes stainless steels, low-alloy steels, and soft magnetic alloys, depending on the mechanical, thermal, or magnetic requirements of the part. Dimensional stability is achieved through calibrated sintering profiles and controlled atmosphere conditions. In-line inspections and post-process evaluations ensure that parts conform to specified tolerances and material performance benchmarks.

Additional capabilities include in-house heat treatment and CNC machining, which support mechanical finishing, surface modification, and final dimensional adjustments. The full production flow is traceable and optimized for repeatability in defense-grade applications.

International experience, local expertise

MimecriUSA is part of Ecrimesa Group, a European leader with over 30 years of experience in MIM for defense, aerospace, and medical sectors. Our U.S. operations combine this global expertise with local agility—meeting the specific needs of American defense contractors with responsive technical support and domestic production.

Considering MIM for your next defense application? Get in touch to know more.

by

by